Universal Forest Products Case Study – “A Better Solution”

Problem: One weekend, 48 hours, to remodel the only men’s restroom on the factory floor.

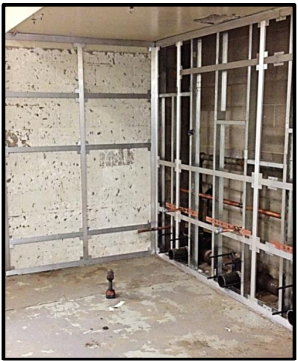

Solution: After total demolition, preassembled Railset Frames were attached to the exposed concrete and metal stud structure. The Railset frames provided a square, level, flush and plumbed mounting surface for plywood cladding. The perfectly aligned plywood sub-wall provided the flush site line surface for glueing large format, 120” x 30” x 1/8” porcelain panels. All panels installed flush with perfect joint lines. The level and plumbed decorative wall mating perfectly and simplified the installation of the plumbing fixtures and toilet partitions.

The restroom demolition started at 5:00pm Friday. The total restroom remodel opened at 7:00am

Monday.

Manufacture Facilities

Universal Forest Products, Riverside, CA

Universal Forest Products, Riverside, CA

The UFP factory men’s locker room remodel was completed in 2.5 days. Demolition and refinishing occurred between 4:30PM Friday and 7:00AM Monday. The Railset Web was instrumental in meeting this schedule.

Universal Forest Products, Riverside, CA

- Web Sections pre-assembled off site prior to project start reduced installation time.

- The Web masked irregular concrete and steel stud wall surfaces. No wall prep required.

- The Web afforded a perfect application of the plywood substrate and the 3mm porcelain panels.

- The contractor said, “The Web reduced the substrate and decorative panel installation by 50%.”