Kaiser Hospital Case Study – “A Better Solution”

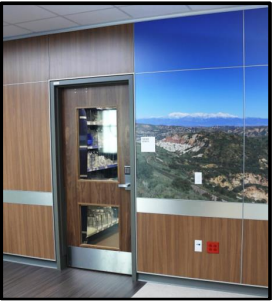

Problem: The hospital corridor design specified backlighted graphics to be flush with the metal, woodgrain, and printed graphic panels.

Solution: Averve’s Railset provided clearance behind the Railset frame for the wiring and transformers. Metal and woodgrain panels attached to the Railset frames in perfect alignment with the graphic panels.

Problem: For Kaiser, the patient headwall is an important design element in every patient room. The headwall is also the central location of all patient care utilities. The utilities, installed behind the drywall, must be brought forward to surface mount on the decorative panels of the headwall.

Solution: Railset’s frames are preassembled in the pattern of the utility outlets. The frame is quickly mounted to the sub-wall as one unit. Each frame is assembled to address the special needs of each patient room. Panels are face fastened for easy removal. Scutcheon plates for patient utilities are screw fastened to the face of the panels.

The Railset frame supports the multi purpose of the patient headwall; warmth of design, a standard template for patient care outlets, and a flat surface for easy maintenance.

Site Issue Solution

Kaiser Permanente Hospital Corridors, Irvine, CA

Kaiser Permanente Hospital Corridors

Kaiser Fabrications needed a frame system that would fix luminous panels and decorative panels flush along hospital corridors. The Web’s hardware accommodated the varying panel depths while masking all sub-wall irregularities.

Kaiser Irvine location is an active facility.

The Kaiser Irvine location is an active facility. To control noise and dust in the active floors, Kaiser Fabrication pre-assembled Web sections and pre-fit panel sizes off site to expedite the decorative panel installations. The square, level frames masked all corridor wall surface irregularities to insure perfect flush panel joinery.

The luminous panel and the decorative panel faces were flush on the corridor walls. The mix included back-lit photographs, Opaque printed photographs, Cherry faux print panels and aluminum veneer panels.