VA Hospital Case Study – “A Better Solution”

Problem: Healthcare givers sought ways to reduce patient stress while undergoing critical testing procedures. The magnetic imaging room interior was targeted but patient care backlog demanded a fast remodel with minimal disruption to the adjoining area. Non-ferrous materials were required for the remodel due to magnetic draw form the room’s equipment. Demolition of existing wall materials was not an option due to the sensitivity of the imaging equipment to dust.

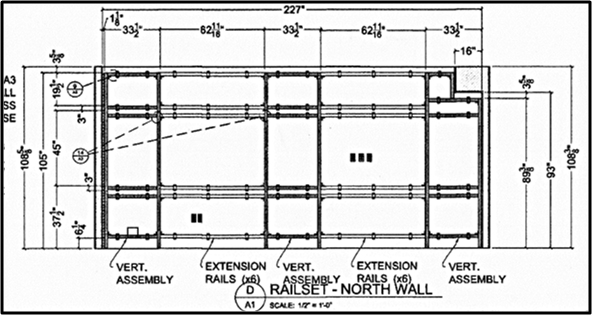

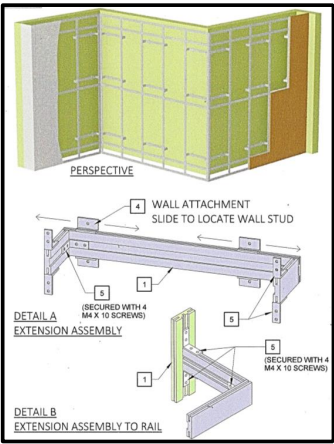

Solution: Railset’s web is assembled from non-furious aluminum rails and brackets. All Web rail joints are secured with non- furious stainless steel machine screws. To expedite the installation, Web frames were pre-assembled off site before scheduled remodel. The web was extended from the existing wall to create a cavity to accommodate the LED Monitor and transformer. Panels were fabricated off-site. No site cutting noise or dust involved in the cavity wall installation. No punch list problems identified after installation. The Railset Cavity Wall Panel installation met the installation schedule.

Health Care

VA Hospital Magnetic Imaging Room

VA Hospital Magnetic Imaging Room

The hospital’s Magnetic Imaging Room remodel included decorative woodgrain paneling and the installation of a rotating nature scene LED Screen to provide a tranquil environment. The remodel installation had to be fast with minimal area disruption, noise, and dirt. The Railset Web Panel system accommodated these requirements by having the wall frames and panel sizing fabricated off-site.

VA Hospital Magnetic Imaging Room

The Railset Web hardware is very compatible with limitations posed by magnetic imaging. The hardware is non-ferrous aluminum assembled with stainless steel screws immune to the strong magnetic current of the room equipment .