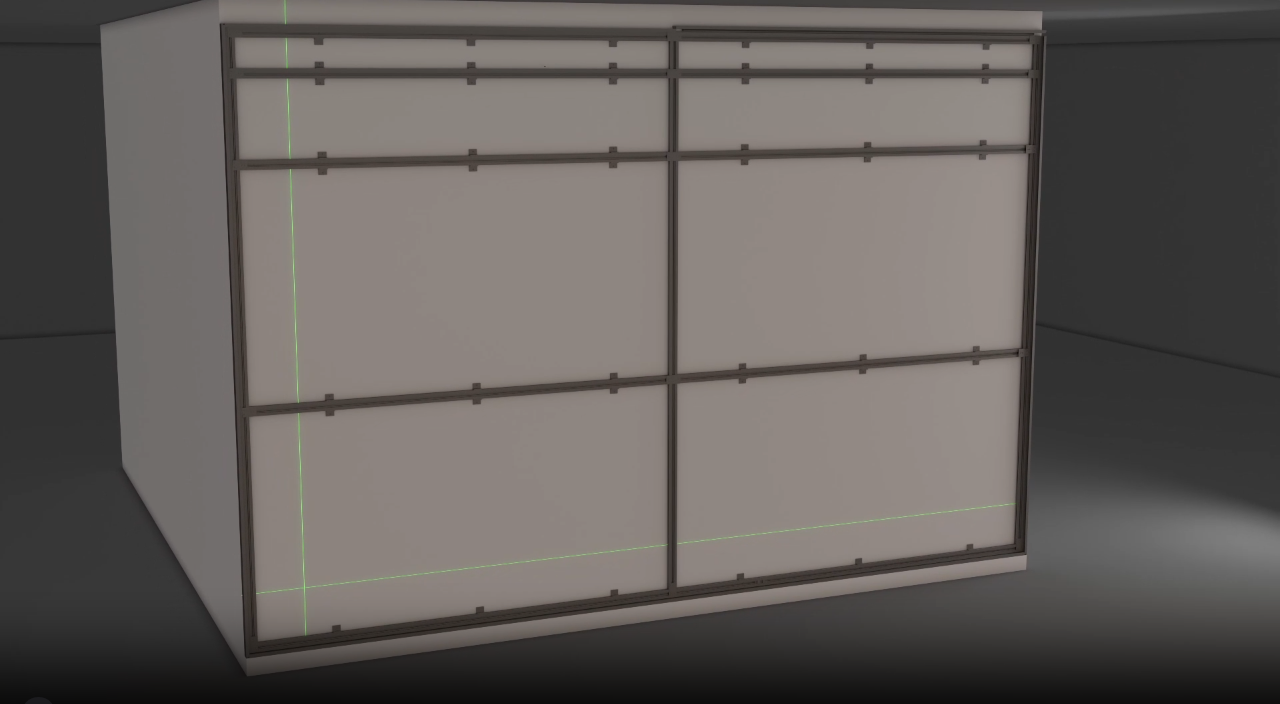

Decorative Panel Hardware System “A Better Solution”

Averve’s hardware assemblies are square, level, and easy to plumb webs. Seven pre-engineered aluminum

components provide a pallet for wall, ceiling, column, soffit, cavity frames, and non-loading partition frames.